The WISEE-EDM model

Short overview

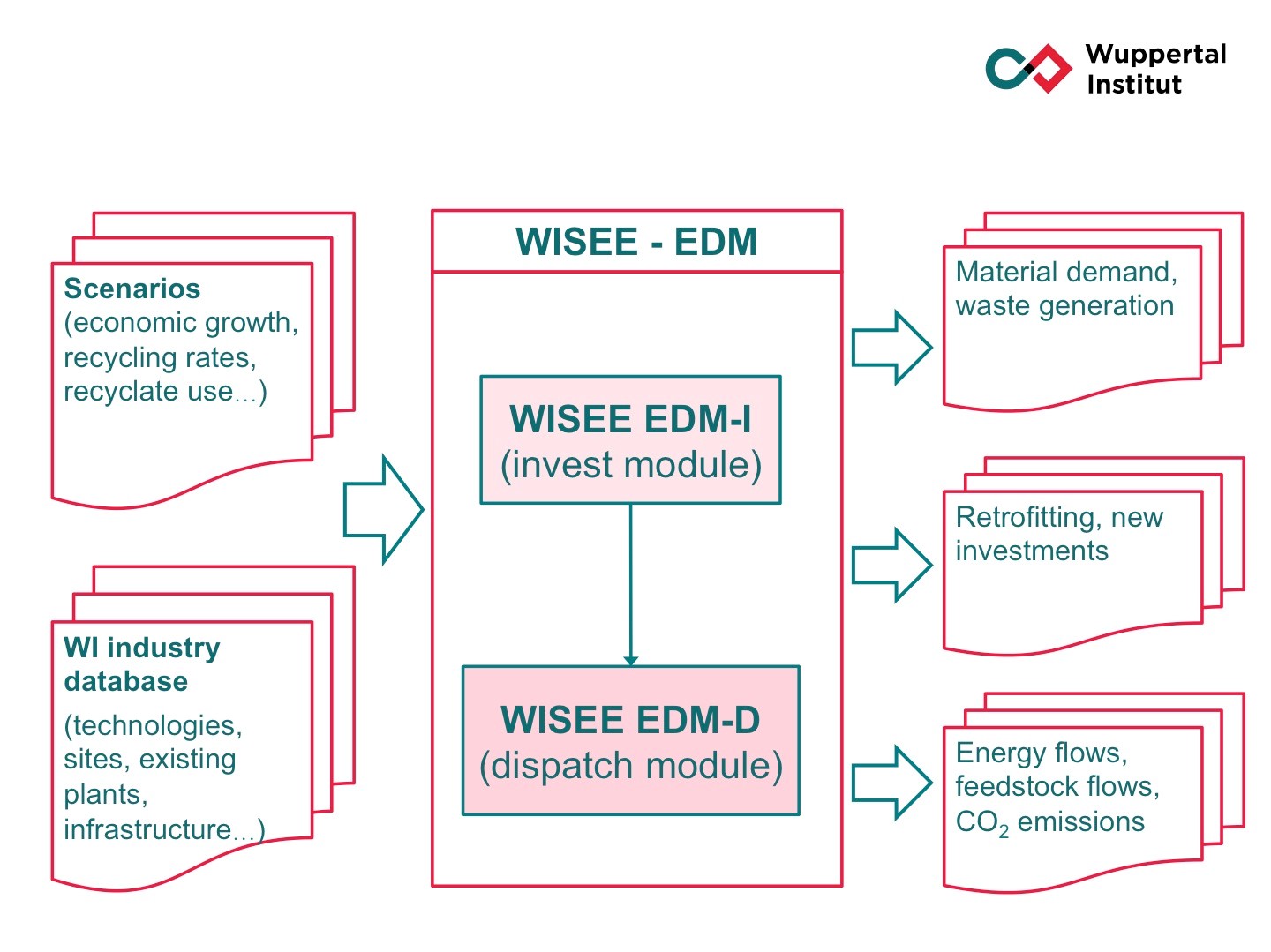

The industrial modules of WISEE-EDM are used to analyse possible futures of an industrial production system and to derive technically consistent paths to them, starting from the current production system.

Typical questions to the models are, for example:

- "Which technologies will enable compliance with set CO2 emission reduction targets in 2050?"

- "When does a phase-in of break-through technologies need to start in order to reach a target state while maintaining usual reinvestment cycles?"

- "What energy sources are needed for a target pathway, in what quantities, when and where?"

- "What do future production networks look like technologically and geographically?"

The models have a high level of technical detail and offer a variety of options for adapting the analysis to scenario-specific assumptions. They are therefore particularly suitable for developing scenarios in exchange with stakeholders.

The models and tools cover different industrial sub-sectors and levels of analysis and have a range of different purposes, for example material flow analysis (EDM-S) and investment optimization (EDM-I). The following gives a very brief account of each of the models in the family (see figure 1):

- The EDM-D draws on production levels that need to be provided as an input and on the EDM industry database (see below) to calculate the site-specific capacity utilization of production processes and for determining the resulting energy requirements and CO2 quantities. Among other things, the EDM-D enables a rule-based switch between energy carriers over time, whereby a substitution rule is created for a sector or process and made dependent on conditions (such as availability of an H2 infrastructure or availability of a CO2 infrastructure) and can be limited to certain locations or regions (e.g. states, NUTS-3 areas). Furthermore, the EDM-D balances by-products of industrial production (hydrogen, process steam, steam cracker by-products, coke oven, blast furnace and converter gases) and their further use in other processes at the level of sites or cross-site H2 and steam networks.

- The EDM-I optimises the Europe-wide investments in production plants of the chemical industry from an economic point of view over a given period of time, taking into account the demand for end products in different years as well as transport costs between locations, taking into account product pipelines that exist between locations today. The EDM-I requires the specific production costs of individual technologies as well as other cost parameters. These are stored in the model, but can also be varied if necessary. The optimisation also results in the use of feedstock and the production quantities per (intermediate) product at different locations. A version of the EDM-I for the steel industry is currently under development (Dec 2022).

- The EDM-S is a multi-regional dynamic Material Flow Analysis (MFA) of polymers technically based on the ODYM framework (Open Dynamic Material Systems Model). It aims to answer such questions as “which polymers are demanded in which quantities by which consumer sectors in any given year?” and “Which polymers enter the waste stream in which quantities and after how long in which use sectors in any given year?”. A version of the EDM-S for the steel industry is currently under development (Dec 2022).

- The EDM-D_EU is a simplified version of the EDM-D that is used for the energy intensive industries except steel, chemicals and refineries at the EU27(+UK) level. It is used for activity-based modelling of mitigation pathways at country level (i.e. without explicit representation of production capacities).

- The EDM-C is a tool for the cement sector that enables a structured derivation of cement and clinker required to satisfy an externally defined service demand for concrete buildings. This tool enables the consideration of developments and reduction levers at different levels of the cement and concrete sector ranging from efficiency of concrete use in concrete construction (e.g. leaner components) through binder shares in concretes and market shares of new binders to the use of different types of cements with various clinker contents.

- The EDM-Steam is a tool to define technical pathways for the production of steam required for industrial production and to calculate according energy demands and CO2. It differentiates CHP and boilers fueled by different energy carriers as well as heat pumps.

- The EDM-NE extrapolates energy demand for and CO2 emissions of the non-energy intensive industries based on economic indicators, efficiency parameters and technology shifts. It differentiates the non-energy intensive industry into three sectors and considers four different heat levels for each of them (room temp., < 150°C, 150-500°C, >500 °C).

The EDM-D and EDM-I modules draw on an extensive database of industrial plants currently (2022) covering the following industries:

- for EU-27+3: iron & steel, basic chemicals, refineries

- for Germany in addition: pulp & paper, non-ferrous metals, cement, lime, glass

(see below for details on the database)

The model results cover selected years (typically 5-year steps) within the specified simulated time frame (e.g. 2020 - 2050).

Key features of the WISEE-EDM model

High level of technological detail

Energy requirements and CO2 emissions are calculated based on the (assumed) physical production of goods. The database underlying the WISEE-EDM industry modules includes:

- Approx. 800 production sites in Europe. These are stored with GIS data and assigned to the EU member states and various NUTS levels. The linking of chemical industry sites and refineries by feedstock and product pipelines is also stored in the database. Furthermore, the (future) times of a connection of sites to a CO2 or H2 infrastructure can be specified (depending on the scenario).

- Approx. 200 technologies (e.g. blast furnace, steam cracker, rotary kiln) with their respective specific energy requirements, process-related emissions, selected material inputs and typical technical lifetimes. Technologies are stored at different development and efficiency levels: at the standard of the European average of the years 2000 to 2005 (“default”) as well as the currently best available technology (“BAT”) and assumed further improved processes in the future (“BAT+”).

- More than 2600 industrial production facilities. The production facilities are specified in terms of the technology used (see above) and their production capacity. For particularly energy-intensive plants, the year of construction is also stored. All production plants are assigned to individual sites.

Consideration of industrial co-products

In the EDM-D the production of steam, steel gases and hydrogen as by-products of industrial production as well steam cracker by-products are accounted for at each site or within the inter-site networks stored in the database, and is taken into account in the calculation of (remaining) energy requirements and the operation of industrial power plants. For the production of steel and basic chemicals, balances are also prepared for selected quantities of materials (educts and products).

Consideration of production chains

The investment module EDM-I is characterized by a consideration of complex production chains in connection with transport possibilities and costs of intermediate products.

Climate module & emissions granularity

CO2 emissions are calculated based on the (assumed) physical production of goods considering the site-specific efficiency of applied technologies and the choice of energy carriers as well as the use of carbon capture technologies (if any). In the EDM-D CO2 emissions are calculated for each production plant and can be aggregated to NUTS 3-, NUTS- 1, national and European levels.

Socioeconomic dimensions

Production levels

Production levels are a main driver of the model. Economic growth is a main input variable to the definition of production level scenarios used by the model. Furthermore, effects of behavioural changes on production levels (e.g. less demand for cars) can be included in the specification of production level scenarios. The fine-grained differentiation of products by the model allows for a detailed representation of developments in the various industrial sectors.

Impacts of political and societal discourses

The model is flexible to include impacts of political and societal discourses on the industrial production system such as the future (non-)availability of infrastructures (e.g. CO2-infrastructure) and technologies.

Mitigation/adaptation measures and technologies

The model is capable of including technical mitigation measures such as:

- Recycling and production of secondary products

- Changes to production levels of particular goods

- Innovative production technologies (e.g. DRI for steel making) and energy conversion technologies (e.g. high-temperature heat pumps)

- Energy-efficiency of industrial production and energy conversion technologies

- Fuel switches

- Carbon capture and storage / use

The model does not include adaptation measures.

Economic rationale and model solution

The core principle behind the investment related part of the model (EDM-I) is that of societal costs of industrial production of a given amount of products. EDM-I is an optimization model that minimizes the investments and (simplified) operation costs over the whole simulated time period (while considering the value of assets at the end of the time period).

The dispatch model (EDM-D) and other models in the model family do not involve economic considerations but are purely technical models that are driven by externally set scenarios for production levels and technology replacement (e.g. as derived by use of the EDM-I).

Overall, the “solution” of the integrated model family typically consists of an iterative process of scenario outline (production levels, technology shifts, energy carrier shifts, infrastructure layout, …), model application and expert and stakeholder discussions.

Key parameters

Each of the models and tools in the model family have their specific key parameters. The following abstracts from the single models to key parameters for scenario development with the model family.

Demand for products / Production levels

TDemand for products (including intermediary products) is a key driver of the model family. It can be externally set in the EDM-D / EDM-D_EU modules or be derived from other models such as the EDM-S, the EDM-I and the EDM-C. An ideal-typical interplay of the models for the chemical industry, for example, is to use the EDM-I to derive production levels (and capacities) for final and intermediary products that are required to satisfy an externally set demand for final products – while the EDM-S is used to calculate the amount of waste materials available as a further input to the EDM-I.

Technological development

Other central parameters are the years at which innovative production technologies are assumed to be available on an industrial scale and the speed of market penetration with BAT / BAT+ technologies.

Infrastructure development

The time at which infrastructures (H2, CO2) will be available (in the future) is a (externally set) key influence factor for technology shifts and fuel switches. In the EDM-D it can / needs to be defined on a site-specific basis per scenario while the EDM-D_EU operates on the basis of capacity shares connected to infrastructure per country and year.

Policy questions and SDGs

Key policies that can be addressed

While the WISEE-EDM does not feature a policy interface or endogenously simulates the effects of policies, it is able to incorporate the effects of a range of different types of policies through adaptation of the model parameters:

Energy policy

The invest module (EDM-I) can directly assess the effects of energy related policies that affect prices (tax, subsidies) or availability of energy carriers (e.g. coal exit). In the dispatch module (EDM-D) the standard energy demand associated with the usage of particular production technologies may also be amended in a rule-based manner to cover fuel switches (e.g. coal exit, replacement of natural gas by biomethan etc.).

R&D related policies

The model can assess the effects of R&D related policies by variation of the year from which on technologies are available on an industrial scale level. The model may be used to check the influence of such measures on the development of the industrial production stock – depending on the age composition of the plants, availability of infrastructure, and other factors. Furthermore, policies that support the diffusion of innovative technologies can be represented through variation of the replacement rate of standard technologies through best available technologies as well as further improved technologies.

Infrastructure related policies

The model can assess the effects of infrastructure related policies and regulations through variation of industry sites’ connection to infrastructures (EDM-D) / variation of the capacity shares connected to innovative infrastructures per country and year (EDM-D_EU).

Implications for other SDGs

WISEE-EDM does not automatically calculate the implications on non-climate SDGs. However, it is possible to use its outputs (CO2, energy) and calculate impacts for certain indicators framed in the SDG agenda.

Model presentation

Video

Slides

Download slides in pdfRecent use cases

| Paper DOI | Paper Title | Key findings |

|---|---|---|

| https://doi.org/10.1016/j.eist.2019.05.004 | Risks and opportunities associated with decarbonising Rotterdam’s industrial cluster | The Port of Rotterdam industrial cluster is heavily exposed to future decarbonisation policies, as most of its activities focus on trading, handling, converting and using fossil fuels. Using a mixture of qualitative and quantitative methods, the article explores three pathways whereby the port’s industry can maintain its strong position while significantly reducing its CO2 emissions and related risks by 2050. Depending on mitigation target and choice of mitigation strategies, future technologies and infrastructure may differ greatly. Almost full decarbonisation of the cluster can be achieved by 2050, possibly even without CCS. |

| Simulating geographically distributed production networks of a climate neutral European petrochemical industry | The paper describes quantitative scenarios on a possible evolution of the EU petrochemical industry towards climate neutrality. The cost-optimization model used to develop the scenarios describes at which sites investments of industry in the production stock could take place in the future. Around 50 types of products, the related production processes and the respective sites have been collected in a database. The processes included cover the production chain from platform chemicals via intermediates to polymers. Pipelines allowing for efficient exchange of feedstock and platform chemicals between sites are taken into account as well. The model draws on this data to simulate capacity change at individual plants as well as plant utilization. Thus, a future European production network for petrochemicals with flows between the different sites and steps of the value chain can be sketched. The scenarios described in this paper reveal how an electrification strategy could be implemented by European industry over time with minimized societal costs. | |

| https://doi.org/10.1016/j.apenergy.2019.114218 | Optimal system layout and locations for fully renewable high temperature co-electrolysis | Many favourable locations for high-temperature co-electrolysis (HTCOE) exist across Europe. HTCOE can become economically competitive for currently discussed CO2 prices. |

References

Schneider, C., Lechtenböhmer, S., & Samadi, S. (2020). Risks and opportunities associated with decarbonising Rotterdam’s industrial cluster. Environmental Innovation and Societal Transitions (35).

Schneider, C. & Saurat, M. (2020). Simulating geographically distributed production networks of a climate neutral European petrochemical industry. Paper accepted for presentation at ECEEE 2020 conference.